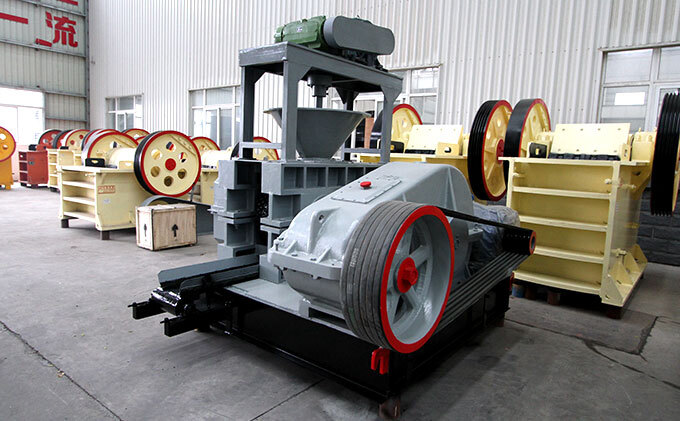

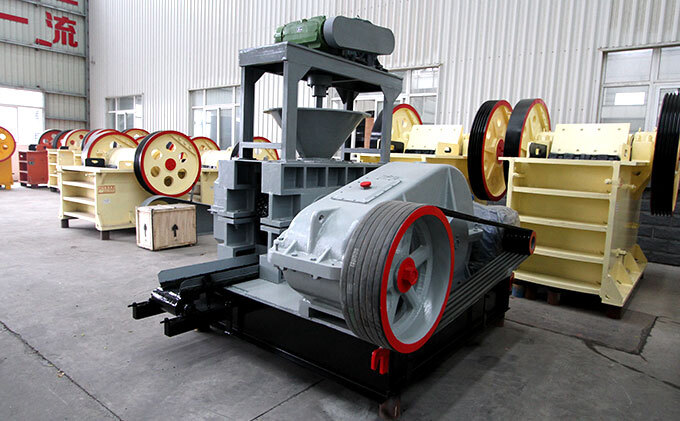

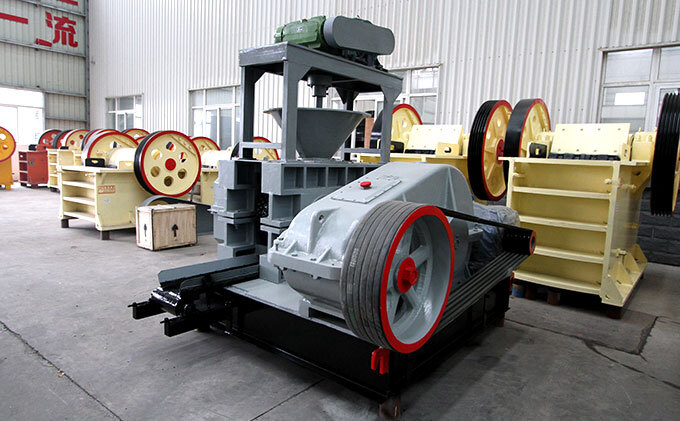

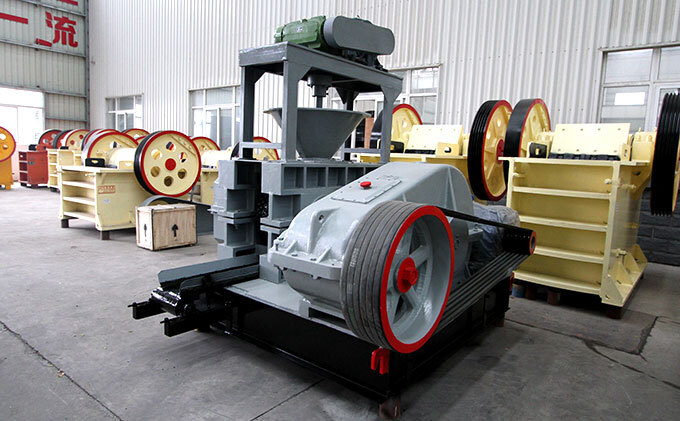

Hydraulic Briquetting MACHINES

Price 225000 INR/ Unit

MOQ : 1 Unit

Hydraulic Briquetting MACHINES Specification

- Product Type

- Hydraulic Briquetting Machine

- General Use

- Industrial

- Material

- Mild Steel (Body), Alloy Steel (Roller)

- Production Capacity

- 1200-1500 kg/hr

- Product Shape

- Cylinder / Pillow / Square

- Weight (kg)

- 2800

- Type

- Hydraulic Press

- Working Theory

- High Pressure Hydraulic Compacting

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Optional

- Cooling System

- Water Cooling System

- Voltage

- 380-415 V

- Motor

- 30 HP Electric Motor

- Roller Quantity

- 2

- Roller Diameter

- 310 mm

- Roller Material

- Alloy Hardened Steel

- Briquette Size

- 60 mm (Diameter)

- Dimension (L*W*H)

- 3200 mm x 900 mm x 1750 mm

- Feature

- Robust Structure, Easy Installation, Low Maintenance

- Color

- Blue / Grey

- Safety Features

- Emergency Stop, Overload Protection

- Pressure Capacity

- Up to 250 Ton

- Noise Level

- Below 80 dB

- Cycle Time

- 45 seconds

- Control Panel

- Digital/Manual

- Briquette Density

- 1.2-1.4 g/cm3

- Raw Material Acceptance

- Biomass, Metal, Sawdust, Coal Dust

- Hydraulic Oil

- Anti-wear 68/32

- Oil Tank Capacity

- 250 Liters

- Feed Size

- Up to 25 mm

Hydraulic Briquetting MACHINES Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 10 Days

- Packaging Details

- Less power consumption Unmatched performance High operational fluency Easy to operate Specification: Roller dia: 660 mm.(approx) Roller width: 225 mm. ( approx) Size of briquette: Our standard size 65 x 40 x 20 mm. (approx) Gearbox: To suit Motor: 45 Kw Capacity: 5 - 10 Tons./Hr Material to be briquetted: Chrome Ore, Coke, Manganese Ore, Iron Ore fines

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Less power consumption Unmatched performance High operational fluency Easy to operate Specification: Roller dia: 660 mm.(approx) Roller width: 225 mm. ( approx) Size of briquette: Our standard size 65 x 40 x 20 mm. (approx) Gearbox: To suit Motor: 45 Kw Capacity: 5 - 10 Tons./Hr Material to be briquetted: Chrome Ore, Coke, Manganese Ore, Iron Ore fines

About Hydraulic Briquetting MACHINES

Assisted by a competent team and advanced machinery, our organization is manufacturing, exporting and supplying a superior quality gamut of Hydraulic Briquetting Press. This press consists of chassis by fabricated joist & channel which duly stress relieved and properly machined for proper alignment. The provided press is used in ceramic, refractory, chemical industries and milk plant and is suitable for proper agglomeration of feed mix. Offered press is manufactured using premium quality components and the latest technology by our experts. Also, this Hydraulic Briquetting Press is made available from us at market leading prices.

Features:

-

Less power consumption

-

Unmatched performance

-

High operational fluency

-

Easy to operate

- Roller dia: 660 mm.(approx)

- Roller width: 225 mm. ( approx)

- Size of briquette: Our standard size 65 x 40 x 20 mm. (approx)

- Gearbox: To suit

- Motor: 45 Kw

- Capacity: 5 - 10 Tons./Hr

- Material to be briquetted: Chrome Ore, Coke, Manganese Ore, Iron Ore fines

Robust Structure and High Output

Built from mild steel and featuring alloy-hardened steel rollers, this hydraulic briquetting machine can withstand continuous industrial use. The system boasts a production capacity of up to 1500 kg/hr, ensuring high efficiency for both small and large manufacturing facilities. Its rigid design and quality components minimize downtime and extend operational lifespan.

Versatile Raw Material Acceptance

Designed to process a variety of feedstocks, including biomass, metal shavings, sawdust, and coal dust, the machine accepts feed sizes up to 25 mm. Its adaptability enables users from various industries to recycle multiple waste types while achieving uniform, high-density briquettes. Materials are compacted using extreme hydraulic pressure for optimal output.

Intelligent Operation and Safety

Whether you prefer digital or manual controls, the briquetting machine features a user-friendly panel. Automatic operation and optional PLC control enable easy, precise influences over production. Safety features such as emergency stop and overload protection are integrated, providing confidence and compliance with industrial standards.

FAQs of Hydraulic Briquetting MACHINES:

Q: How does the hydraulic briquetting machine operate to form dense briquettes?

A: The machine utilizes high-pressure hydraulic compacting, applying up to 250 tons of force to compress raw materials into briquettes with densities between 1.2-1.4 g/cm. Automatic cycles (45 seconds each) ensure consistent shape and strength, and the robust alloy steel rollers help achieve uniform compaction.Q: What types of raw material can be processed with this briquetting machine?

A: This model is engineered to accept various raw materials such as biomass, metal scraps, sawdust, and coal dust. Materials should be up to 25 mm in size, making it suitable for diverse industrial recycling needs and maximizing waste-to-product efficiency.Q: When is maintenance required, and how is it simplified on this machine?

A: Routine maintenance is minimized due to the machines robust structure, anti-wear hydraulic oil (68/32), and water cooling system. Regular checks on the oil tank (250 liters) and rollers ensure smooth operation; servicing intervals depend on usage conditions but the system is designed for easy access and upkeep.Q: Where can this hydraulic briquetting press be installed?

A: Its compact dimensions (3200 mm x 900 mm x 1750 mm) allow installation in most industrial manufacturing environments. The machine supports both indoor and factory floor setups, requiring a standard voltage supply (380-415 V) and proximity to a water source for the cooling system.Q: What benefits does using this machine provide to an industrial operation?

A: Users gain high-output briquetting (up to 1500 kg/hr), reduced waste volume, and easy waste recycling. The systems automated features, low noise (below 80 dB), and versatile raw material acceptance improve productivity and environmental compliance, while advanced safety features optimize operator protection.Q: How is the production process controlled and monitored?

A: Operators can choose between manual and digital control panels, with optional PLC integration for automated monitoring. Emergency stop and overload protection systems provide real-time safety interventions, ensuring reliable and continuous operation during each 45-second production cycle.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Briquetting Press Machine Category

Industrial Briquetting Press Machine

Price Range 200000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Briquette Machines

Automatic : Yes

Motor : AC Motor

Feature : Lower Energy Consumption

PAULS ENGINEERING ENTERPRISES

GST : 19AAFFP6480L1ZM

GST : 19AAFFP6480L1ZM

17/7/A, Narasingha Dutta Road, Kadamtala, Howrah - 711101, West Bengal, India

Phone :08045477091

|

PAULS ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry